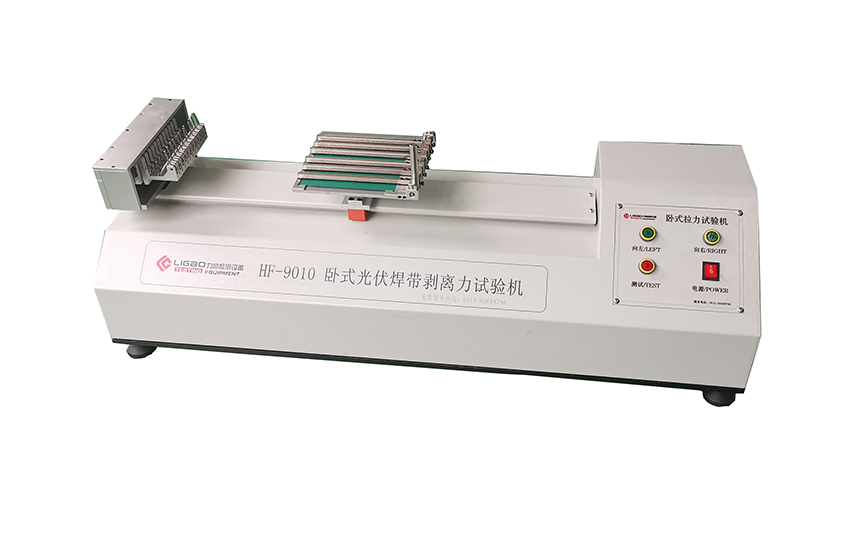

HF-9010E 12BB Photovoltaic Welding Strip Peeling Force Testing Machine

I. Function and Application

1. Purpose

This machine is designed to test the peel strength performance of solar silicon cell ribbons. It adopts a horizontal tensile testing method, making the operation more convenient.

2. Application Scope

This equipment is independently developed by our company specifically for the photovoltaic industry. It is designed for peel strength and tensile strength testing of silicon wafers, silicon materials, solar cell modules, and other related products.

The machine is equipped with five load cells and integrated with Ligao’s self-developed intelligent software, allowing simultaneous use of all five sensors. Test data can be transmitted and displayed in real time.

With nine testing stations working simultaneously, it greatly reduces manual operation and testing time. Single-station or dual-station testing is also supported, and the accuracy remains unaffected. A single-sided test on one solar cell can be completed in less than one minute.

Due its unique horizontal design, the machine occupies minimal space, is user-friendly, and effectively addresses the fragility of silicon-based solar cells during testing.

1. Load Cell: 100N

2. Control Speed: 50–500 mm/min

3. Testing Stations: 12 stations, can operate independently or simultaneously

4. Overall Accuracy: Class 0.5

|

Load Cell(N) |

Standard Loading(N) |

Accuracy(N) |

Indication error(%) |

Acceptable error(%) |

|

20 |

20 |

≤±0.1 |

≤±0.5% |

≤±0.5% |

|

50 |

50 |

≤±0.25 |

≤±0.5% |

≤±0.5% |

|

100 |

100 |

≤±0.5 |

≤±0.5% |

≤±0.5% |

|

200 |

200 |

≤±1 |

≤±0.5% |

≤±0.5% |

5. Test Force Measurement Range: 0.1%–100% FS

6. Force Control Rate Adjustment Range: 0.02–FS /s

7. Relative Error of Force Control Rate: Within ±0.5% of the set value

8. Test Force Display Resolution: 1/±500,000 of the full scale (constant resolution across full range)

9. Displacement Accuracy: ±0.5% (Displacement resolution: 0.001 mm)

10. Relative Error of Displacement Indication: Within ±0.5% of the displayed value

11. Displacement Resolution: 0.025 µm

12. Displacement Rate Control Accuracy: Within ±0.5% of the set value

13. Total Displacement: Encoder 1000 P/R, accuracy = 0.001 mm

14. Test Space: Crosshead travel distance approximately 400 mm

15. Display System: Computer monitor display

16. Control System: Ligao's proprietary professional measurement and control software

17. Drive System: AC variable frequency motor (Power: 0.18 kW)

18. Surface Finish: Electrostatic powder coating with DuPont powder, baked at 200°C for hardening

19. Power Supply: 220V, 50Hz – suitable for standard laboratory environments

20. Lead Screw: §45 high-precision, zero-backlash ball screw, durable and deformation-resistant. Origin: Taiwan TT

21. Grips: Special lightweight aluminum alloy (Al6061 or designated grade) grips and blocks, designed for the low-force and brittle nature of silicon cells. Polished and anodized surface, lightweight, rustproof, and wear-resistant

22. Grip Surface Finish: Anodized finish for refined appearance and durability

23. Guide Rod Bearings: Japanese NSK linear ball bearings

24. Guide Rods: Made by Korea TAIKING, surface hardened and hard chrome plated, hardness >HRC60 (high wear resistance)

25. Reduction Gear: Precision vacuum die-cast aluminum reducer from Italy OTIS

26. Dust Protection: Taiwan-made YIDI bellows-type dust cover, protecting the lead screw from dust and debris

27. Protective Cover: Transparent acrylic safety cover for clear observation during testing

28. Multi-layer Safety Protection:

(1) Mechanical travel limit protection via limit switch

(2) Software overload and stroke limit protection; breakpoint stop protection

(3) Emergency stop function in case of abnormal conditions

※ "Dear valued customer,Thank you for choosing Ligao Testing Equipment. By selecting our products, you have also chosen our robust customer service and the assurance of using high-quality testing equipment.

1.Our production base is located in Suzhou, specializing in the research and development as well as production of mechanical performance, environmental simulation, optical equipment, and fatigue equipment.

2.We offer comprehensive customizations for laboratory equipment in various fields such as new energy, childcare, home furnishings, and power tools.

3.Our laboratory capabilities are accredited with ISO/IEC 17025:2005 training, CNAS capability accreditation, and DILAC accreditation.

4.We provide comprehensive services for laboratory construction, including overall investment budgeting, comprehensive local planning, construction, facility matching, and integrated project evaluation.

5.Our professional maintenance personnel have undergone specialized training to meet your after-sales service requirements.

6.Our company is ISO 9001 certified, and our constant temperature and humidity test chambers are included in the national energy-saving and emission reduction standards.

7.We offer free product testing and welcome you to visit our factory for guidance and inspection.

Thank you for your trust in Ligao Testing Equipment. We are committed to providing you with the best products and services."