I. Main Purpose and Application Scope:

Standards Referenced:

GB/T22435-2008: "Motorcycle and Lightweight Motorcycle Lightweight Alloy Wheels"

ISO8644-2006: "Motorcycles - Lightweight Alloy Wheels - Test Methods"

GB/T6147-92: "Test Machine Packaging, Packaging Labels, and Storage and Transport Technical Requirements"

II. Main Technical Specifications:

Main Impact Hammer Weight: 100kg

Auxiliary Impact Hammer Weights: 30kg×1, 20kg×3, 10kg×1

Impact Hammer Head Width: No less than 200mm

Impact Hammer Displacement: No less than 200mm

Adjustable Wheel Mounting Bracket: No less than 200mm

Hammer Release Load: 200kg

Digital Display of Hammer Impact Height

Wheel Test Piece Outer Diameter After Tire Installation: φ200~φ350mm

Equipment Main Body Dimensions: 970mm (L) × 600mm (W) × 1750mm (H)

Motor Power: ≤1kw

III. Structure and Functional Features:

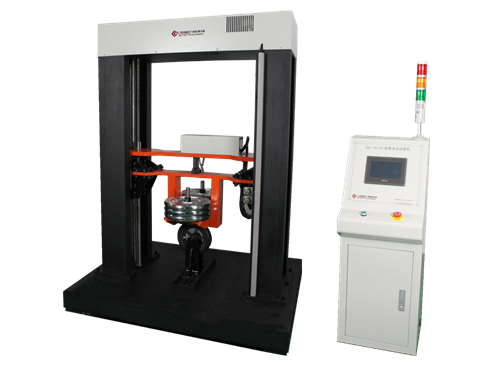

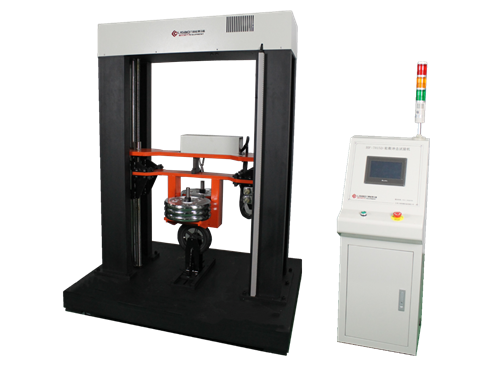

The Electric Vehicle Wheel Radial Impact Test Machine is mainly used for testing the radial impact resistance of lightweight alloy wheels used in electric vehicles.

The test machine consists of the main body, parameter measurement and display unit, high-voltage control unit, test accessories, and other components.

The main body features a frame structure, with the motor placed above. The motor drives the impact hammer to rise via a transmission screw, and the height is collected by a photoelectric encoder, directly displayed on a secondary instrument, ensuring accurate and reliable test data.

The hammer release is controlled by an electromagnetic device, with a mechanical safety feature, and is manually triggered via a handheld controller, ensuring safe and reliable operation.

A scale is installed on the frame to directly observe the hammer height.

The test machine includes a high-voltage control box to drive the lifting motor and pneumatic components.