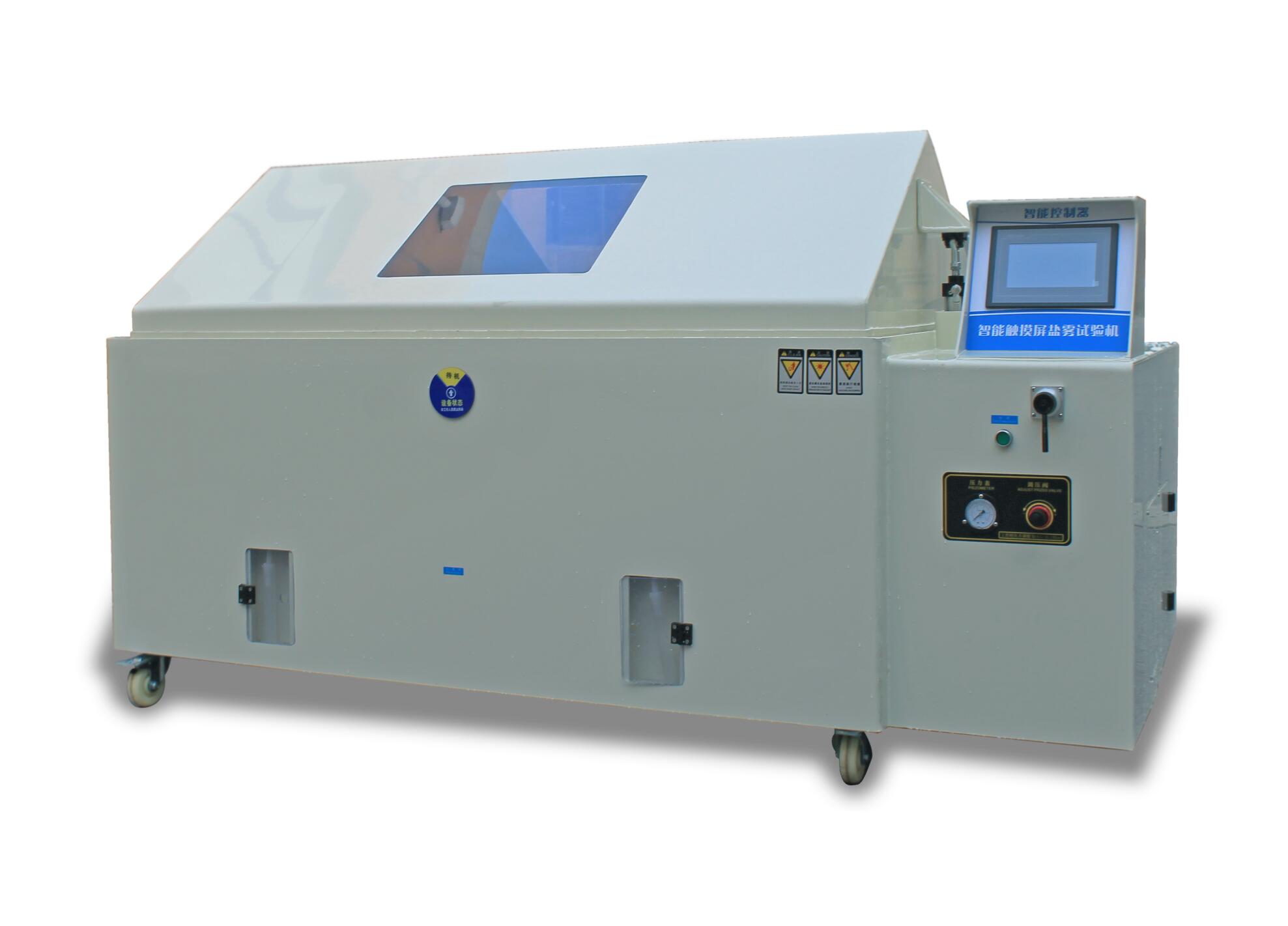

HF-8006 Intelligent Salt Spray Testing Machine (LCD Display)

1. Functions and Applications:

This Salt Spray Testing Machine is designed to evaluate the corrosion resistance quality of surface treatments on various materials, including coatings, electroplating, organic and inorganic films, rust-preventive oils, and chemical treatments. The goal is to assess the long-term corrosion resistance of finished products.

By using a salt solution or acidic salt solution in a controlled environment with specified temperature and relative humidity, this equipment performs accelerated corrosion tests. It simulates the degree of damage materials or products may experience over a certain period.

The machine can be used to:

2. Standards:

3. Technical Specifications:

|

Model NO. |

HF-8006C |

HF-8006B |

HF-8006A |

HF-8006AL |

HF-8006LX |

|

Internal Chamber Size cm |

60×45×40 |

90×60×50 |

120×80×50 |

160×100×60 |

200×100×60 |

|

External Dimensions |

110×67×118 |

141×91×122 |

200×115×145 |

240×135×145 |

280×135×155 |

|

Test Chamber Volume |

108L |

270L |

480L |

800L |

1200L |

|

Saltwater Tank Volume |

15L |

20L |

40L |

40L |

60L |

|

Power Supply |

AC 220V 50HZ 2.0KW |

AC 220V 50HZ 2.5KW |

AC 220V 50HZ 3.5KW |

3-Phase AC 380V 50HZ 5.0KW |

3-Phase AC 380V 50HZ 7.0KW |

|

Technical Specification |

Test Chamber Temperature |

RT+5℃~50℃(Based on Test Standard) |

|||

|

Temperature Fluctuation |

≤±1.0℃ |

||||

|

Salt Spray Deposition Amount |

1~2ml/h/80cm2 |

||||

|

Spray |

Spray Tower |

Special conical disperser, adjustable spray size, ensuring even mist distribution. |

|||

|

Nozzle |

PYREX glass precision nozzle. |

||||

|

Spray mode |

Neutral, acidic, and copper-accelerated salt spray test types are selectable; custom types can also be chosen, but the set parameters must comply with the relevant salt spray testing standards. In program-based testing, more test types can be defined. For detailed information, please refer to the program testing introduction. |

||||

|

Test Temperature:

|

Test Room:35℃±1℃-Saltwater testing method.(NSSAASS) |

||||

|

Saturated air tank:47℃±1℃-Saltwater testing method.(NSSAASS) |

|||||

|

PH:6.5 ~ 7.2-Saltwater testing method.(NSSAASS) |

|||||

|

Test Room:50℃±1℃-Corrosion resistance testing method.(CASS) |

|||||

|

Saturated air tank:63℃±1℃-Corrosion resistance testing method.(CASS) |

|||||

|

PH:3.0~ 3.2-Corrosion resistance testing method.(CASS) |

|||||

|

Samples layer |

Two layers, standard mold for single-step forming, suitable for approximately 15° to 30° tilt tests (ensuring that the test solution does not deposit on the sample). |

||||

|

Compressed air pressure. |

1.00±0.01(kg/cm²) |

||||

|

Mist removal method |

The mist is expelled by air pressure, and the lid of the chamber is designed with a conical shape, forming a 120° apex angle. This design helps prevent salt mist droplets from directly falling onto the sample, ensuring the accuracy of the test. |

||||

|

Intelligent Touchscreen Controller |

Laboratory Temperature Control:35~55°C, Accuracy: 0.1°C (MCGS True Color Touchscreen) Taiwan VT4810 PID Automatic Calculation |

||||

|

Heating Tank Liquid Expansion Overtemperature Protection Controller:0~110°C (Made in Korea) |

|||||

|

Saturation Tank Temperature Controller:4770°C, Accuracy: 01°C (Dual Display)PID Automatic Calculation |

|||||

|

Total Time Counter:0~99999 minutes

|

|||||

|

Pressure Adjustment: Primary Pressure Regulator (Coarse adjustment, located at the back) Secondary Pressure Regulator (Fine adjustment, located at the front)

|

|||||

|

Material |

PVC Brand new A-grade panel material.Transparent observation window. |

||||

|

Note |

Special requirements for non-standard,Can be customized |

||||

4. Product Features

※ "Dear valued customer,Thank you for choosing Ligao Testing Equipment. By selecting our products, you have also chosen our robust customer service and the assurance of using high-quality testing equipment.

1.Our production base is located in Suzhou, specializing in the research and development as well as production of mechanical performance, environmental simulation, optical equipment, and fatigue equipment.

2.We offer comprehensive customizations for laboratory equipment in various fields such as new energy, childcare, home furnishings, and power tools.

3.Our laboratory capabilities are accredited with ISO/IEC 17025:2005 training, CNAS capability accreditation, and DILAC accreditation.

4.We provide comprehensive services for laboratory construction, including overall investment budgeting, comprehensive local planning, construction, facility matching, and integrated project evaluation.

5.Our professional maintenance personnel have undergone specialized training to meet your after-sales service requirements.

6.Our company is ISO 9001 certified, and our constant temperature and humidity test chambers are included in the national energy-saving and emission reduction standards.

7.We offer free product testing and welcome you to visit our factory for guidance and inspection.

Thank you for your trust in Ligao Testing Equipment. We are committed to providing you with the best products and services."