I. Purpose of the Baby Stroller Dynamic Durability Testing Machine:

The CNS6263 Baby Stroller Dynamic Durability Testing Machine is manufactured according to the CNS hand-pushed baby stroller dynamic durability testing standard. The test method involves placing a dummy baby in the stroller, fixing the stroller onto the test platform, and adjusting the conveyor belt speed to 1.4¡À0.1 m/sec (5kw/h ¡À3.6 kw/h). After continuous testing for 64 hours, the stroller is visually inspected for damage. Once the set number of cycles is reached, the machine automatically stops. The machine is equipped with a photoelectric device to prevent damage to the testing machine caused by handle or rubber band breakage. This machine is suitable for testing the dynamic durability of the stroller's rear wheels and body when simulating road conditions during movement.

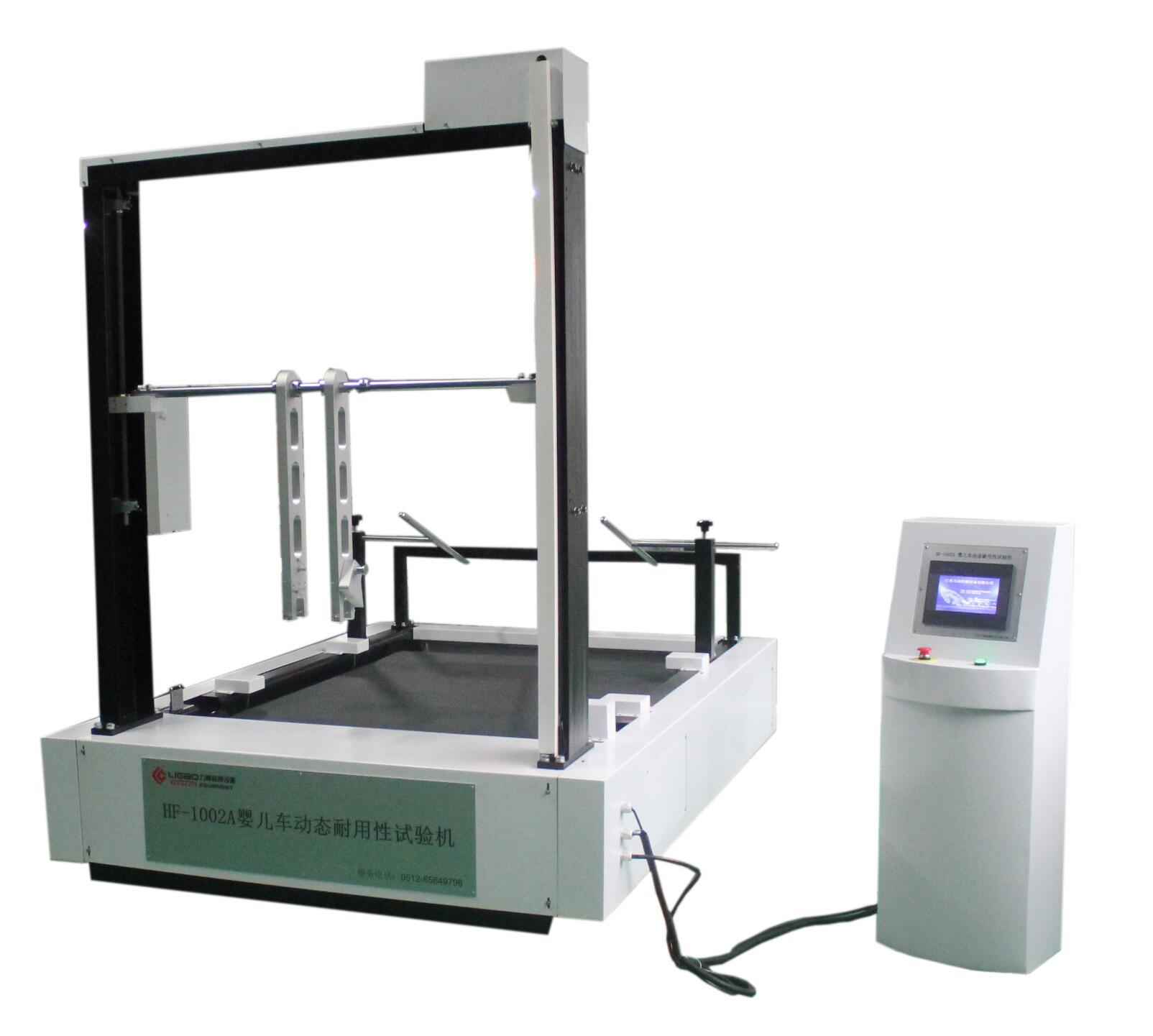

II. Technical Specifications of the Baby Stroller Dynamic Durability Testing Machine:

1 Model: HF-1002 Baby Stroller Dynamic Durability Testing Machine

2 Testing Standards: Manufactured according to AS/NZS2088:2000, ASTM-F833, CNS 6263-11, BSL-1996, EN1888:2003, and other relevant standards

3 Test Item: Single-seat stroller body (front and rear)

4 Testing Speed: 5kw/h ¡À0.1kw/h (adjustable)

5 Drive Method: Roller-driven fabric rubber conveyor belt, reinforced with a special aluminum alloy conveyor belt

6 Motor Power: AC220V, 3HP

7 Vertical Adjustment Range: Max 300mm

8 Effective Width: Max 1000mm

9 Test Cycle Counter: PLC digital display

10 Load Capacity: Max 50 lbs

11 Power Supply: AC220V, 2KW

12 Machine Dimensions: 2100 x 1260 x 2000 mm

13 Machine Weight: Approx. 400 kg

14 Impact Block Shape: Trapezoidal, semi-arc, or specified

15 Remarks: Custom designs available according to customer requirements

¡ù "Dear valued customer,Thank you for choosing Ligao Testing Equipment. By selecting our products, you have also chosen our robust customer service and the assurance of using high-quality testing equipment.

1.Our production base is located in Suzhou, specializing in the research and development as well as production of mechanical performance, environmental simulation, optical equipment, and fatigue equipment.

2.We offer comprehensive customizations for laboratory equipment in various fields such as new energy, childcare, home furnishings, and power tools.

3.Our laboratory capabilities are accredited with ISO/IEC 17025:2005 training, CNAS capability accreditation, and DILAC accreditation.

4.We provide comprehensive services for laboratory construction, including overall investment budgeting, comprehensive local planning, construction, facility matching, and integrated project evaluation.

5.Our professional maintenance personnel have undergone specialized training to meet your after-sales service requirements.

6.Our company is ISO 9001 certified, and our constant temperature and humidity test chambers are included in the national energy-saving and emission reduction standards.

7.We offer free product testing and welcome you to visit our factory for guidance and inspection.

Thank you for your trust in Ligao Testing Equipment. We are committed to providing you with the best products and services."