I. Product Principle Description:

Test Purpose:This machine is used to simulate the flipping rotation of the battery pack and battery system around the X-axis or Y-axis. There is no need to refix the battery pack during the X-axis/Y-axis switching process. The performance is judged by observing the phenomena during the test.

Test Method Description:

The test object is the battery pack or system.

Rotate the test object around the X-axis at a speed of 6¡ã/s for 360¡ã, then rotate in 90¡ã increments, keeping each 90¡ã increment for 1 hour, then stop at 360¡ã and observe for 2 hours.

Rotate the test object around the Y-axis at a speed of 6¡ã/s for 360¡ã, then rotate in 90¡ã increments, keeping each 90¡ã increment for 1 hour, then stop at 360¡ã and observe for 2 hours.

II. Compliance with Standards:

GB/T 31467.3-2015 ¡°Lithium-ion Power Battery Pack and System for Electric Vehicles ¨C Part 3: Performance Requirements and Test Methods¡±

III. Test Evaluation Results:

Requirements: The battery or system should show no leakage, no shell rupture, no fire or explosion, and should maintain reliable connections and structural integrity. The insulation resistance after the test should be no less than 100¦¸/V.

IV. Operation Control:

Operating Mode:Program-controlled mode, fixed-value mode

Control Mode:PLC touch screen control and PC remote control, allowing both close-range and remote control

Test Computer:Equipped with a Lenovo ThinkServer series business computer, CPU with Intel Core i5 processor (3rd generation), 1GB dedicated graphics card, 4GB memory, 19.5-inch display, 500GB hard drive. The corresponding parameters and program operation can be performed on the computer with real-time data display. Remote monitoring is possible, and the monitoring and control computer can be placed in the control room.

Control System Interface:The operating system interface is available in Chinese or English, and the external control software can also be in Chinese or English.

Program Settings:The flipping speed, time, angle, number of flips, and intermediate rest time can be set.

Real-time Monitoring:The computer can monitor and record rotational speed, angle, time, cycle counts, etc., and store test and setting curves and data for at least 6 months.

V. Equipment Structure and Product Features:

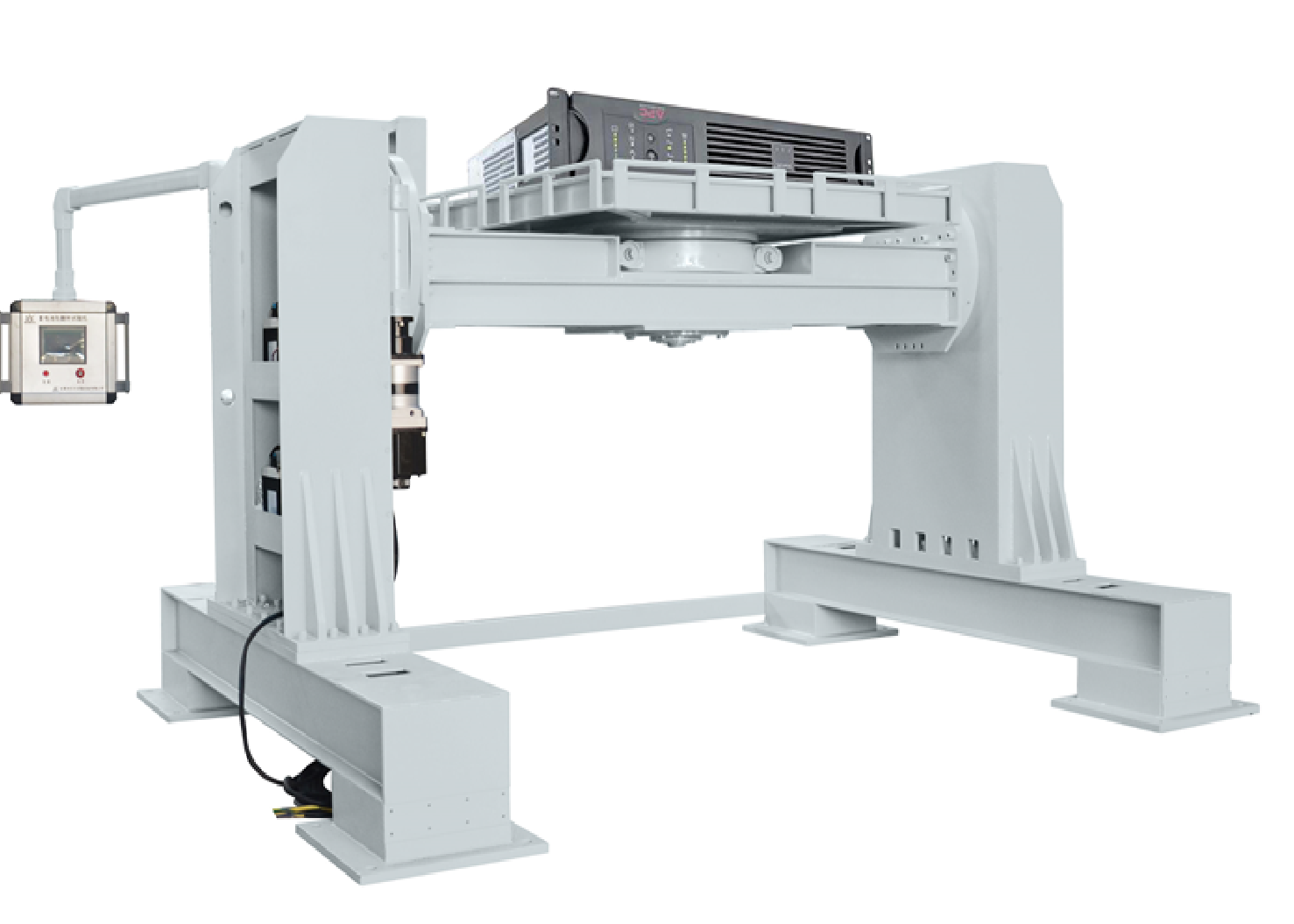

The battery flipping test machine uses a motor combined with a screw rod to achieve the electric flipping of the battery. The device is surrounded by a protective cover (as shown in Figure 1-3).

Protective Cover Material:Cold-rolled steel plate, 3mm thick, treated with advanced electrostatic spray coating.

Flipping Control:The flipping mechanism is controlled by a servo motor, ensuring precise control over the flipping angle.

Control Mode:PLC automatic/manual control mode.

Overall Structure Description:a. The main frame is welded from high-strength steel, ensuring strong load-bearing capacity and durability. The four pillar directions have triangular reinforcements. b. The equipment base is made of 45# cast steel, which provides high rigidity. c. The surface in contact with the test piece on the rotating platform has an insulating and corrosion-resistant coating. d. An optoelectronic sensing device is installed around the equipment. When the operator installs the battery pack, the system will remain in the stopped state and will not perform any actions. Additionally, if an operator accidentally enters the operating area during the test, the system will automatically stop.

Battery Fixing Method:The battery is secured using adjustable fixtures combined with straps, ensuring that the flipping platform can rotate around its X-axis and Y-axis without needing to refix the battery pack during switching. a. The rotating platform has 10cm ¡Á 10cm or 20cm ¡Á 20cm matrix positioning holes for securing the test samples, and corresponding installation accessories (such as bolts and straps) are provided. b. The platform also has sliding grooves around its edges, which can be used to adjust and secure batteries of different sizes. c. Two cylinders are located on the fixture width direction, assisting in fixing the battery to ensure stability during the test.

Rotating Connection and Guidance:The rotating shaft uses high-strength stainless steel bearings for smooth connection.

Three-color Warning Light:Located at the top of the machine, the light will flash and sound an alarm when the equipment encounters a fault, notifying the operator to stop and handle the issue.

Overload Protection Device:When the equipment experiences issues such as leakage, overvoltage, or overcurrent, it will automatically activate an alarm.

Lighting System:An explosion-proof LED light is installed on the top of the test box, providing dustproof, explosion-proof, and fireproof capabilities. The light's casing is easy to replace.

Custom Color Options:The overall color of the equipment can be customized according to customer requirements.

Control Box:To ensure testing, the control box is separated from the test instrument, achieving long-distance wired control. The connection wire is 8-10 meters long, providing effective protection.

Monitoring Function:The protective cover has a monitoring system that can observe the operational status of the equipment and the test piece within the working area. It includes an adjustable-focus video camera with a pixel resolution of no less than 8 million. The images are displayed on a 19-inch or larger monitoring screen, and the system can store video for at least one month, with cyclic recording functions.

Emergency Stop:The equipment has an emergency stop switch that requires two actions to reset after being pressed. An additional emergency stop switch is provided in the control room.

Smoke and Flame Detection:The work area is equipped with smoke and flame detection features. Once a hazard is detected, the system will automatically trigger an alarm.

VI. Equipment Specifications:

Test Object Weight:1000kg

Test Object Dimensions (mm):W1500 ¡Á D1200 ¡Á H1000

Platform Load Capacity:1000kg

Platform Dimensions:W1800 ¡Á L1500mm

Platform Center Height from the Ground:¡Ý1200mm

Rotation Direction:Clockwise or counterclockwise

Rotation Speed:Continuously adjustable from 1¡ã/s to 16¡ã/s, with a common test speed of 6¡ã/s

Drive Mode:Servo motor-driven

Control Mode:PLC touch screen and PC remote control, allowing both close-range and remote control

Battery Placement Surface Material:SUS#304 stainless steel with a Teflon coating, insulating and corrosion-resistant

Outer Box Material:Cold-rolled steel plate with advanced spray coating treatment

Rotation Angle Increment:90¡ã, the platform includes 10cm ¡Á 10cm or 20cm ¡Á 20cm matrix positioning holes for securing test samples, with installation accessories such as bolts and straps.

Total Rotation Angle:0¡ã-360¡ã with continuous rotation at any angle, and the platform can stop and hold at any angle. The battery pack does not need to be refixed during the axis switch.

Rotation Speed Resolution:¡Ü0.4¡ã/s

Angle Resolution:0.4¡ã

Speed Control Accuracy:0.5¡ã/s

Angle Control Accuracy:0.5¡ã

Time Control Accuracy:¡À0.1%

Specific Test Requirements:

Rotate the test object around the X-axis at 6¡ã/s for 360¡ã, then rotate in 90¡ã increments, holding each increment for 1 hour. Stop at 360¡ã and observe for 2 hours.

Rotate the test object around the Y-axis at 6¡ã/s for 360¡ã, then rotate in 90¡ã increments, holding each increment for 1 hour. Stop at 360¡ã and observe for 2 hours.

Equipment Dimensions:2600 ¡Á 2400 ¡Á 2400mm (W ¡Á D ¡Á H)

Weight:Approx. 3T

Power Supply:AC220V¡À10%, 50Hz

Power Consumption:2kW

VII. Protection System:

Overvoltage Protection:The sensors have built-in pressure ranges to prevent excessive pressure from damaging the sensor and drive motor.

Phase Loss and Reverse Phase Protection Switch

Stroke Limit Protection

Circuit Fuse Overcurrent Protection

Overload Protection

¡ù"Dear valued customer,Thank you for choosing Ligao Testing Equipment. By selecting our products, you have also chosen our robust customer service and the assurance of using high-quality testing equipment.

1.Our production base is located in Suzhou, specializing in the research and development as well as production of mechanical performance, environmental simulation, optical equipment, and fatigue equipment.

2.We offer comprehensive customizations for laboratory equipment in various fields such as new energy, childcare, home furnishings, and power tools.

3.Our laboratory capabilities are accredited with ISO/IEC 17025:2005 training, CNAS capability accreditation, and DILAC accreditation.

4.We provide comprehensive services for laboratory construction, including overall investment budgeting, comprehensive local planning, construction, facility matching, and integrated project evaluation.

5.Our professional maintenance personnel have undergone specialized training to meet your after-sales service requirements.

6.Our company is ISO 9001 certified, and our constant temperature and humidity test chambers are included in the national energy-saving and emission reduction standards.

7.We offer free product testing and welcome you to visit our factory for guidance and inspection.

Thank you for your trust in Ligao Testing Equipment. We are committed to providing you with the best products and services."